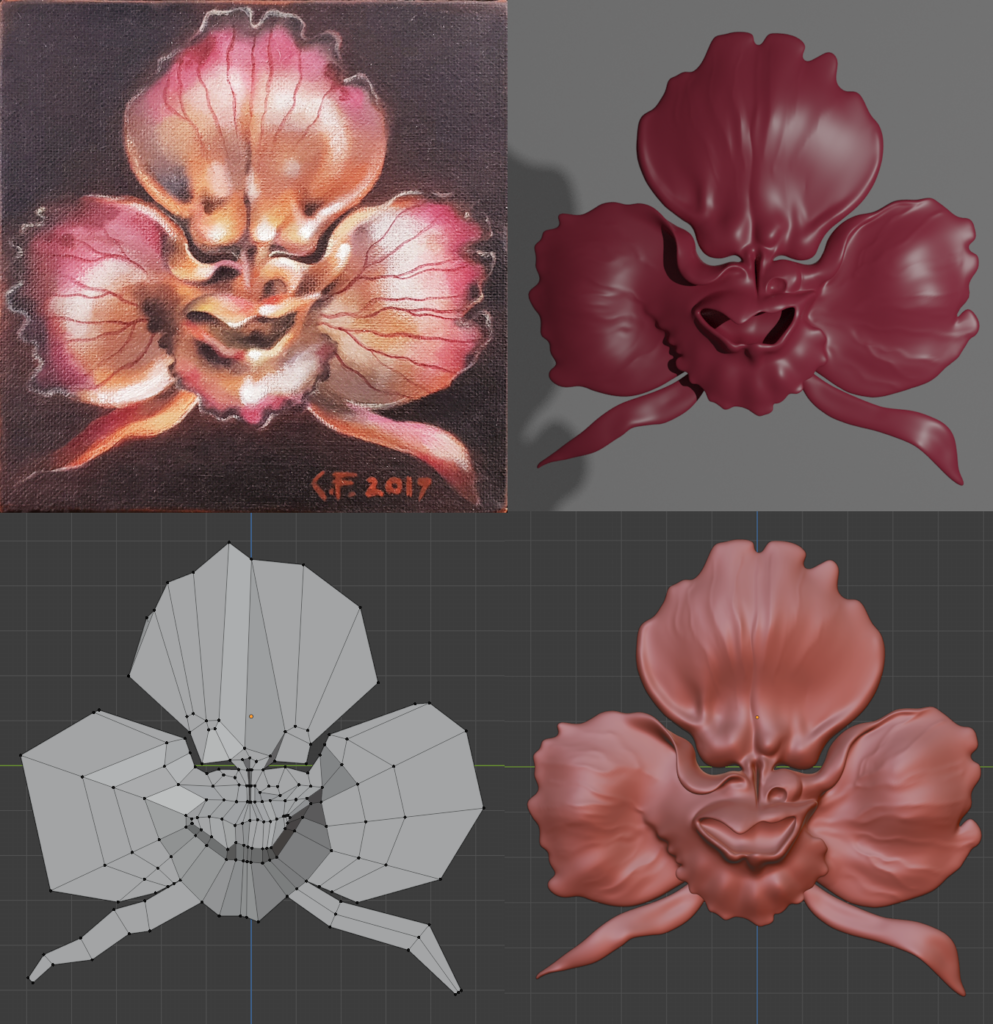

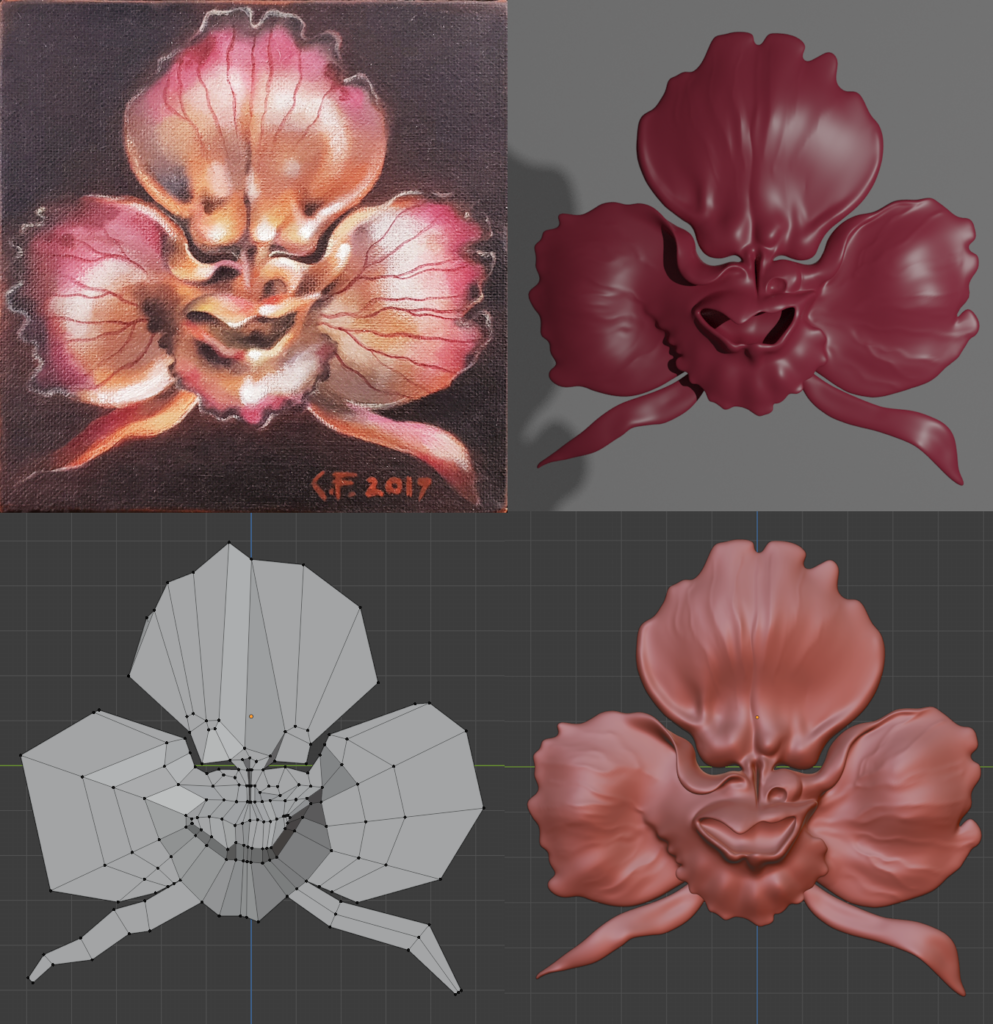

2D Image to 3D Model

Designs begin as conceptual drawings or are modeled freehand on the computer.

The models are then rendered to gain an accurate impression of how the finished object will look in any color or material.

Printing

3d models are converted into files that can be processed by a 3D printer. Depending on the model, either a Fused Deposition Modeling (FDM) printer or a Stereolithography (SLA) printer is used to create the physical object.

SLA printing is used for small resin objects with lots of fine detail, such as jewelry, while larger objects are manufactured from starch-based polylactic acid (PLA) or composite filaments with an FDM printer.

Post-Processing

and Assembly

Final touches are important for a clean, finished look. Model supports are carefully removed and coatings may be applied to obtain different surface textures.

Each print is inspected to ensure that all complete products are flawless prior to entering the shop. The Coil is committed to offering quality 3D-printed items using this technology’s capabilities to their fullest potential.